Hydraulic Fracturing Process

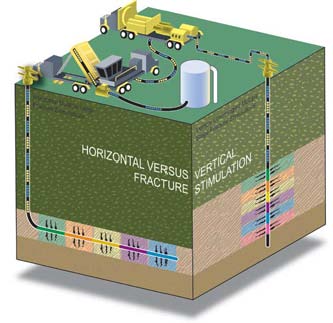

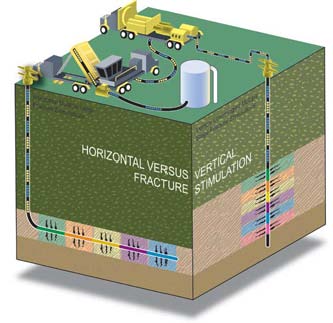

After a well is drilled, the casing is perforated, typically with explosive charges. A “pad” of fluids is then injected, at a sufficient pressure and rate, to fracture the formation surrounding the perforations. The fractured formations are typically located thousands of feet below the water table. Next, a “slurry,” which consists of fracing fluids and proppant, is injected to extend and develop the fracture. Proppants are generally either sand, resin-coated sand, or ceramic. Finally, the pressure is released and the fluid is flowed back from the well. A majority of the proppant remains trapped in the formation, which keeps the fractures open and allows gas/oil to flow. See this video for an animation of the hydraulic fracturing process.

According to the American Petroleum Institute’s Hydraulic Fracturing Primer, hydraulic fracturing fluids generally consist of 90% water, 9.5% sand, and 0.5% chemicals. An average hydraulic fracturing job uses 3-7 million gallons of water, equating to 150,000 - 350,000 gallons of chemicals per well. The volume of water used in the well is determined by factors including make-up geologic formation and permeability. Smaller-volume fracture treatments are used to create fractures that extend short distances from the borehole. High-volume hydraulic fracture treatments are used where the formation itself has very low permeability, and to produce economic volumes of oil or gas it is necessary to create a large fracture network that extends hundreds or sometimes thousands of feet laterally into the formation. High-volume fracs are used in both horizontal and vertical wells. The chemicals are used to prevent bacteria, corrosion and enhance fracturing, in part by reducing friction, and to protect the well integrity. 750 different chemicals were used by the oil and gas industry for hydraulic fracturing between 2005 and 2009. For a list of the chemicals, see “Chemicals Used in Hydraulic Fracturing,” prepared by the United States House of Representatives Committee on Energy and Commerce.

Another source of information on the chemicals used in hydraulic fracturing is Frac Focus. Frac Focus is a chemical disclosure registry managed by the Ground Water Protection Council and Interstate Oil and Gas Compact Commission. The main purpose of the Frac Focus site is to provide factual information concerning hydraulic fracturing and groundwater protection. Since FracFocus began operation in April 2011 the system has recorded more than 80,000 disclosures from a total of more than 1000 participating companies.

As discussed in the “Regulating Fracing” section on this page and in the Law & Policy pages, some states and the Bureau of Land Management now require that companies disclose the chemicals used to fracture a well. In addition, some companies voluntarily disclose the chemicals used. For example, Halliburton has disclosed the chemicals it uses for hydraulic fracturing in Colorado. Lastly, there is an effort within the oil and gas industry to develop more environmentally friendly fracing fluids.

Picture courtesy of National Energy Board (Canada)

“Low-volume” hydraulic fracturing is typically less than 80,000 gallons of water are used to frac a single well. The resulting fractures may extend only a few feet from the borehole, and are often done to bypass various types of flow blockages that develop next to the wellbore.

In massive hydraulic fracturing, large volumes of water in which various chemicals are dissolved (frac fluid), and proppant, often millions of gallons of water and millions of pounds of sand or other proppant, are injected, to reach hundreds of feet laterally out into the formation. This is needed in very low-permeability formations to allow them to flow oil or gas to the wellbore at rates high enough to be economic. Although many horizontal wells are given massive fracs, many vertical wells and directional non-horizontal wells, such as those in the Williams Fork formation of western Colorado, are also given massive fracs.

Fractures tend to stop at the boundaries between different rock layers. Because the layers in sedimentary rocks are usually nearly horizontal, this causes the fractures to extend horizontally within a layer far more than they extend vertically across the different layers. High pressures are applied during fracturing to push the frac fluid and proppant out far from the well. Once the well starts producing, the pressure gradient is reversed, and frac fluid, oil, gas, and formation water (usually brine) flow back to the well.

Hydraulic Fracturing Controversy: Value versus Risks

Value

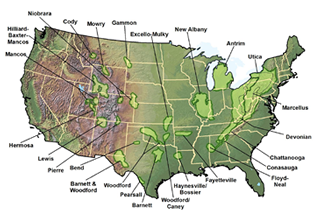

High-volume slick-water hydraulic fracturing, together with the increasing cost of energy, allows for the economical recovery of natural gas from unconventional resources, which have a much lower permeability and flow capacity than conventional resources. The Energy Information Administration estimates that because of hydraulic fracturing, the U.S possesses natural gas resources sufficient to supply the U.S. for approximately 110 years and that shale gas will constitute 45% of the total U.S. natural gas supply in 2035. In addition, due to fracing, an estimated 7 billion barrels of oil are now thought to be recoverable.

Domestic natural gas production is encouraged to reduce dependency on foreign oil and is often seen as a “bridge fuel" to a more renewable energy-based economy because natural gas emits less carbon dioxide per unit of energy than other fossil fuels. Natural gas also requires less processing than petroleum. There are various studies underway to investigate the greenhouse gas footprint of natural gas. A Department of Energy study found that, when compared to coal, the natural gas lifecycle results in one-half the equivalent carbon dioxide emissions.

Photo courtesy of FuelFix.com

Risks

This section discusses the risks attributable to shale gas development, instead of just the hydraulic fracturing process itself. Environmental and public health concerns include ground water contamination, increased traffic and industrial activity, accidents related to improper chemical handling, surface spills, waste disposal, air quality, and water use.

Groundwater Contamination from Below-Ground Activity

There have been suspected instances of groundwater contamination from the hydraulic fracturing process. The EPA did studies in Pavillion, Wyoming and in Colorado, where there were reports of groundwater contamination from fracing chemicals or natural gas. But in many cases, a lack of baseline sampling has prevented landowners from proving whether alleged contamination is connected to hydraulic fracturing.

There are a very few instances where improper drilling practices, most often defective casing or inadequate cementing of oil and gas wells, have allowed natural gas or briny formation water to leak into drinking water aquifers, contaminating water wells. This can be a problem whether or not a well is hydraulically fractured. In a properly constructed oil or gas well, the borehole is separated from drinking water aquifers by one or more concentric steel casings; the spaces between the separate concentric casings, and the casing and the borehole wall is filled with cement up to a level dictated by the state agency (in Colorado, the Colorado Oil and Gas Conservation Commission).

Some drinking-water aquifers are naturally contaminated with methane (the principal component of natural gas). Sometimes the naturally occurring methane in groundwater can be distinguished from the methane produced in nearby wells by isotopic tests. The Colorado Oil and Gas Conservation Commission investigates reports of drinking water contamination due to oil and gas wells.

There are also many wells in which the source of the methane cannot be determined by analysis after the contamination is reported; in such cases the only way to know is by sampling and analyzing the water in nearby wells before drilling, to establish a baseline. In Garfield County, western Colorado, for instance, although the methane in some water wells has been traced to nearby leaking gas wells, in the majority of cases, the source of methane in water wells -- whether natural or due to gas drilling -- is unknown.

Duke researchers discovered that concentrations of thermogenic methane, with a chemical signature consistent with deep shale thermogenic methane sources, increase with proximity to natural gas wells in Pennsylvania. It is currently unknown whether improper drilling techniques or conduits between the fractured shale and groundwater resources caused the contamination. In addition, due to a lack of baseline sampling, it is possible that this thermogenic methane is present naturally.

Improper casing or cementing, poor production pressure management, or drilling in a geologically unstable location may allow fracing fluids to migrate into drinking water supplies. Whether hydraulic fracturing fluids can migrate from the fracing site to drinking water aquifers is highly disputed. This is due in part to the fact that fractured shale is generally separated from groundwater by thousands of feet of impermeable rock strata, and in part due to a lack of peer-reviewed research. There have been no known cases where this occurred.

Groundwater Contamination from Above-Ground Activity

Leaks from produced water impoundments and spills from, for example, trucks hauling returned water or hydraulic fracturing fluids, can cause contamination. Truck traffic can also contribute to erosion and sediment contamination of groundwater, and the EPA estimates that 1 acre of construction site with no runoff controls (including uncontrolled access roads) can contribute 35-45 tons of sediment each year, nearly 16 times the sediment of an acre of natural vegetated meadow. Runoff from natural gas projects may also contain pollutants from contact with the equipment or with fracing fluid and produced water storage facilities. Currently, many believe this above ground activity is a greater threat to drinking water resources than below ground activity. For example, pits used for either storage or disposal of drilling wastes and returned water are believed to have contributed to the contamination in Pavillion, Wyoming.

According to a recent report by the Pacific Institute, surface spills and leaks, stormwater runoff, and truck traffic impacts on water quality may create greater risks to our water supply than hydraulic fracturing. Visit the Pacific Institute website for the full report. According to a recent report by the Pacific Institute, surface spills and leaks, stormwater runoff, and truck traffic impacts on water quality may create greater risks to our water supply than hydraulic fracturing. Visit the Pacific Institute website for the full report.

Best management practices, including use of erosion control practices (see the Reclamation Resources page) and reduction of truck traffic, can help minimize these impacts. For example, through treating and recycling of more than 10 million barrels of produced water, Apache Corporation has helped to reduce potential above-ground impacts by taking more than 80,000 truckloads of water off the road in the Permian Basin region.

Water Usage, Disposal, and Reuse

Water usage varies based on the depth of the well and the number of frac events. A typical well can use several million gallons of water for drilling and fracturing and can return millions of gallons of chemical contaminated or brackish wastewater to the surface both in the short-term and throughout the life of the well. Consequently, regardless of the safety precautions taken in drilling and completing a well, the use of freshwater for drilling and completions raises concerns over depletion of freshwater sources and disposal of the produced wastewater raises concerns over contamination of freshwater sources.

Recognizing these concerns as well as the expense associated with buying, transporting and disposing of water, industry is increasingly recycling its return water into new development through the use of various types of brine treatment techniques. Produced water and frac flowback brine can be treated and recycled for re-use in drilling and completions by a number of treatment techniques. Re-use of brines that have been treated to remove residual hydrocarbon, suspended solids, and scaling minerals can be used directly in oil and gas drilling fluids or fracturing fluids.

Much of the water used to fracture a well, however, stays underground, so groundwater and stream depletion remains a concern in some areas as fresh water continues to be used for fracing. In addition, even when fracing water is reused, it may be necessary to dilute it with fresh water prior to reuse. And, while the EPA estimates 2.3-3.8 million gallons of water are used in the fracturing of each shale gas well, new data suggests this number can vary greatly by region, with operators in Texas’ Eagle Ford shale area using up to 13 million gallons of water per well for fracing alone. Furthermore, the water is typically withdrawn from one source over several days, and can have significant local impacts, especially if it is withdrawn from environmentally sensitive areas.

Additionally, with the rapid spread of hydraulic fracturing in the West and across the Nation, conflicts over water usage are emerging. In 2012 in Colorado, natural gas companies purchased at auction water rights that had previously been largely claimed by farmers, raising questions about the impacts of fracing on agriculture. Similarly, in 2011 in Pennsylvania’s Susquehanna River Basin, 11 water withdrawal permits for natural gas projects were temporarily suspended due to low stream levels. As there was no drought in the basin, the lower stream levels suggest a conflict over limited water resources.

Disposal of fracing wastewater is also a concern. Disposal typically occurs by evaporation that occurs in pits, through surface discharge after treatment in a wastewater treatment plant, or in a permitted disposal well. Because oil and gas waste is exempt from hazardous waste regulations, it can be disposed of in class II wells rather than in Class I hazardous waste wells, resulting in a greater risk of groundwater contamination. Wastewater treatment plants may be unable to adequately treat produced water and higher levels of heavy metals and radioactivity are being reported in wastewater treatment plant discharges.

Nonetheless, reuse or recycling of water can significantly reduce the potential for water depletion and pollution. Examples include:

- The Eagle Ford: In 2015, the wastewater recycling rate in the Eagle Ford is at 30%. It is estimated that by 2019, Eagle Ford operators will be able to recycle half of the wastewater generated during the fracing process. In addition, the use of brackish groundwater as an alternative to freshwater is gaining popularity and in 2015 provides an estimated 20% of the water being used in the Eagle Ford.

- The Permian: Using a combination of brackish groundwater and wastewater, Apache Corporation reports that it is no longer using fresh water at a 35,000 acre field in the Wolfcamp shale of west Texas, one of the Permian region’s hottest oil plays. Water there is so scare that residents in nearby Barnhart, Texas saw their town well go dry in 2013.

- The Piceance: According to an Encana spokesman in the Energy Issue of Headwaters Magazine: “On the Western Slope [of Colorado], Encana recycles more than 95 percent of water used for or produced during drilling . . . Each barrel of water is reused an average of 1.33 times before disposal[.]”

For more on water recycling, reuse and disposal, see the Water Quantity Resource page.

Air Quality

Well completion can result in significant air emissions. After a new well is drilled, operators need to remove fracing fluid and debris from the well bore and the formation. This is called the “flowback” stage. As fluids are removed from the well, large quantities of volatile organic compounds (VOCs), methane, and air toxics, such as benzene, may be produced. Typically, the gases are vented or flared, which may lead to regional air quality problems. Green completions reduce gas losses to the atmosphere during well completions. As is discussed in the Federal Regulatory section, green completions can reduce VOC emissions by 95%. In addition, green completions capture gas that can potentially be sold, resulting in increased revenue.

Additional sources of air emissions include engines used to move equipment and materials, drill wells, and pump fluids, and the materials pumped into the wells. The emissions may include combustion products, particulate matter, VOCs, methane, and air toxics. In June 2012, the Occupational Safety and Health Administration (OSHA) issued a hazard alert for hydraulic fracturing workers due to the potential danger of silica dust. The report identified seven sources of silica dust exposure during fracing, and found that while transporting, moving, and refilling silica to be used as a fracing proppant, dust can be released into the air consisting of 99% silica. High exposure to silica creates a greater risk of silicosis, and can also cause cancer. OSHA recommends a combination of engineering controls, work practices, protective equipment and product substitution, and worker training to minimize the risk. The hazard alert is available on OSHA’s website. For a state comparison of air quality regulations in oil and gas see the LawAtlas site.

Additional Impacts

Fracing is an industrial operation. Fracing operations require the shipment of fracing fluid and equipment to the fracing site. After arriving at the fracing site, the large number of tanker trucks, vehicles, and equipment typically necessitate approximately 1-2 acres surrounding the well site. The well drilling and subsequent fracing are also loud, and the noise, while temporary, can last from two weeks to over a month. Finally, the recovered gases and produced liquids, including on occasion hydrogen sulfide, are odorous and may result in complaints from nearby residents.

|

Regulating Fracing

Oil and gas development is regulated by federal, state, and local governments. This section only discusses the laws and regulations that are directly related to hydraulic fracturing. For example, well casing regulations, while important for ensuring that fracing fluids do not migrate into groundwater, are generally applicable and are not discussed in this section. For information about the regulation of oil and gas development generally, see our Law and Policy Section.

Federal Government

Environmental Protection Agency (EPA)

The 2005 Energy Policy Act exempted the injection of fracing fluids from the Safe Drinking Water Act’s Underground Injection Control Program. (See our Federal Water Quality Laws and Regulations Section and the EPA Hydraulic Fracturing Under the Safe Drinking Water Act webpage for more information about this program.) The 2005 Energy Policy Act exempted the injection of fracing fluids from the Safe Drinking Water Act’s Underground Injection Control Program. (See our Federal Water Quality Laws and Regulations Section and the EPA Hydraulic Fracturing Under the Safe Drinking Water Act webpage for more information about this program.)

The 2005 Energy Policy Act did allow the EPA to continue regulating the use of diesel fuel in fracing fluids. In February 2014, the agency released a permitting guidance document. The guidance document addresses various issues, including information required for a permit application, permit duration, area of review, well construction requirements, monitoring and testing of wells, reporting, and public notifications.

In December 2016, the EPA released the final report of its study: "Hydraulic Fracturing for Oil and Gas: Impacts from the Hydraulic Fracturing Water Cycle on Drinking Water Resources in the United States." The goals of the study were to assess the potential for activities in the hydraulic fracturing water cycle to impact the quality or quantity of drinking water resources and to identify factors that affect the frequency or severity of those impacts. Cases of impacts were identified for all stages of the hydraulic fracturing water cycle. Identified impacts generally occurred near hydraulically fractured oil and gas production wells and ranged in severity, from temporary changes in water quality to contamination that made private drinking water wells unusable. The report notes that available data and information allowed EPA to qualitatively describe factors that affect the frequency or severity of impacts at the local level. However, significant data gaps and uncertainties in the available data prevented EPA from calculating or estimating the national frequency of impacts on drinking water resources from activities in the hydraulic fracturing water cycle. The data gaps and uncertainties also precluded a full characterization of the severity of impacts.

EPA’s Hydraulic Fracturing Study webpage includes the report and executive summary as well as the 2011 study plan, EPA published research, peer review documents, and the draft assessment.

In 2016, the EPA also published a final rule regarding pretreatment standards for disposal of wastewater from unconventional oil and gas extraction such as hydraulic fracturing. Wastewater can be generated in large quantities and contain constituents, including naturally occurring radioactive material, that are potentially harmful to human health and the environment. EPA has regulated direct discharges of oil and gas extraction wastewater pollutants from onshore oil and gas resources to waters of the U.S. since 1979 under 40 CFR Part 435, subpart C, of the Clean Water Act. The new rule prohibits these wastewater discharges to publicly-owned treatment works (POTWs).

In April of 2012 the EPA finalized rule amendments for its Clean Air Act regulations revising the New Source Performance Standards for Volatile Organic Compounds from hydraulically fractured natural gas production wells, requiring reduction of VOC emissions by 95 percent and requiring this to be done through capture after January 2015. For a synopsis of the relevant rule amendments as well as a link to the Rule and EPA summaries, visit our page, 2012 EPA amendment of New Source Performance Standards.

For more background information on water and air issues of hydraulic fracturing, see our Water Quality and Air Quality resource pages.

Department of Energy (DOE) – Hydraulic Fracturing Subcommittee

In 2009, the DOE published Modern Shale Gas Development in the United States: A Primer, which discusses the economics of shale gas development, the current regulatory framework, and environmental considerations. In 2009, the DOE published Modern Shale Gas Development in the United States: A Primer, which discusses the economics of shale gas development, the current regulatory framework, and environmental considerations.

In May 2011, the DOE formed a subcommittee of the Secretary of Energy’s Advisory Board to conduct a review of fracing and make recommendations to improve its safety and environmental performance. The subcommittee was comprised of environmental, industry, and state regulatory experts. The group released its 90-day interim report on August 18, 2011 and its final report on November 18, 2011. This report consists of “consensus based recommendations” to improve the safety and environmental performance of fracing. The final report calls for numerous improvements, including 1) increasing coordination between state and federal regulators, 2) improving air quality in the vicinity of oil and gas development, 3) increasing the use of best management practices, and 4) ensuring that water quality is protected.

Bureau of Land Management (BLM)

Drilling on federal land must comply with both BLM and state regulations.

On March 20, 2015 the Department of the Interior (DOI) released Final Rule to Support Safe, Responsible Hydraulic Fracturing Activities on Public and Tribal Lands. There are four key components of the rule that will go into effect 90 days after the rules were finalized. The components of the rules were summarized in the DOI release of the Rule:

- Provisions to protect groundwater supplies by requiring a validation of well integrity and strong cement barriers between the wellbore and water zones through which the wellbore passes;

- Increase transparency by requiring companies to publicly disclose chemicals used in hydraulic fracturing to the Bureau of Land Management through the website FracFocus, within 30 days of completing fracturing operations;

- Higher standards for interim storage of recovered waste fluids from hydraulic fracturing to mitigate risks to air, water and wildlife;

- Measures requiring companies to submit more detailed information on the geology, depth, and location of preexisting wells to afford the BLM an opportunity to better evaluate and manage unique site characteristics.

Congress – FRAC Act

Congress has tried on occasion to change the regulation of hydraulic fracturing nationwide. The Fracturing Responsibility and Awareness of Chemicals Act (“FRAC Act”), which was originally introduced in both houses of Congress in June 2009 and has been reintroduced in the House of Representatives and the Senate in 2011, 2013, and 2015. The bills would eliminate the hydraulic fracturing exemption from the Safe Drinking Water Act and require public disclosure of the chemicals used in the hydraulic fracturing process.

State Rules

The following highlights some of the important state rules regarding hydraulic fracturing. For more detailed summaries, see the Law and Policy pages. For a comparison of state regulations regarding water quality, water quantity and air quality, see the LawAtlas comparative law database.

Colorado

The Colorado Oil and Gas Conservation Commission (COGCC) requires operators to complete and post a chemical disclosure registry disclosing the chemicals used in hydraulic fracturing operations within 60 days of the conclusion of a hydraulic fracturing treatment, and never more than 120 days after the start of such a hydraulic fracturing treatment. If the specific identity or concentration of a chemical is claimed to be a trade secret it need not be disclosed, but this must be indicated on the disclosure form, and at least the chemical family or other similar descriptor must be included. However, the protected information must be provided to the COGCC if the director requests it by letter because it is necessary to respond to a spill or a complaint. Such information will only be made available to necessary parties, and will not be considered publically available. (COGCC Rule 205A). Chemical disclosures are available at FracFocus.

Colorado requires continuous monitoring and recording of the pressure in the bradenhead annulus and in the annulus between the intermediate casing and the production casing to ensure that fracing fluids are confined to the targeted formations (COGCC Rule 341). If elevated pressures are observed, which may indicate that fluid is leaking from the well, operators must notify the COGCC.

Colorado also requires baseline and post-completion surface water sampling if stimulation activities occur in a Surface Water Supply Area (COGCC Rule 317B) and green well completions (COGCC Rule 805) to reduce harmful air emissions.

Additional rules, applicable to hydraulic fracturing, can be found at this COGCC website and additional information about hydraulic fracturing in Colorado generally can be found at this COGCC website.

The State Review of Oil and Natural Gas Environmental Regulations (STRONGER), is a non-profit, multi-stake holder organization that assists states in documenting their environmental oil and gas development regulations, and comparing their regulatory programs against a set of national guidelines. A STRONGER review panel, which consisted of one industry representative, one state regulator, and one member of the environmental community, recently conducted a review of Colorado’s rules governing the hydraulic fracturing process. STRONGER issued a report, including recommended improvements to the COGCC rules.

Montana

The Montana Board of Oil and Gas Conservation (MBOGC) adopted new rules governing hydraulic fracturing, which became effective on August 26, 2011. Operators must generally obtain approval from the MBOGC before fracing occurs and submit a report of the actual work performed (MBOGC Rule 36.22.1010). In addition, operators must disclose the composition of the fracing fluids (if a trade secret exemption is not applicable) either to the MBOGC or through the FracFocus website (discussed below) or a similar website (MBOGC Rule 36.22.1015). Finally, the MBOGC mandates specific construction and testing requirements for wells that will be fraced (MBOGC Rule 36.22.1106).

New Mexico

The New Mexico Oil Conservation Division requires operators to complete and post a chemical disclosure registry disclosing the chemicals used in hydraulic fracturing operations within 45 days of the conclusion of a hydraulic fracturing treatment. Operators must disclose the total volume of fluid pumped, the maximum ingredient concentration in each additive, and the maximum ingredient concentration in the hydraulic fracturing fluid. However, if the specific identity or concentration of a chemical is claimed to be a trade secret, the division does not require the reporting or disclosure of the chemical. The rule can be found in the New Mexico Administrative Code 19.15.16.19.B.

Operators must notify the New Mexico Oil Conservation District (NMOCD) if fracing has damaged the well casing, casing seat, producing formation, or injection interval (19 N.M.A.C. 15.16.16). The operator must either repair the damage or plug and abandon the well.

New Mexico regulates the construction of pits, closed-loop systems, below-grade tanks, and sumps. (19 N.M.A.C. 15.17). These regulations were developed in response to above-ground contamination concerns associated with hydraulic fracturing. For additional information, see our summary of New Mexico Oil and Gas Regulations.

Wyoming

In Wyoming, Chapter 3 § 45< is specific to hydraulic fracturing. An approved application for a permit to drill is required before fracing can occur and casing integrity testing may be required (WOGCC Chapter 3 § 45(a)). The operator must provide the Wyoming Oil and Gas Conservation Commission (WOGCC) with a detailed description of the well stimulation design (WOGCC Chapter 3 § 45(e)) and the geologic formation (WOGCC Chapter 3 § 45(b)). During stimulation, the pressure in the bradenhead annulus and in the annulus between the intermediate casing the production casing must be continuously monitored (WOGCC Chapter 3 § 45(i)). If elevated pressures are observed, which may indicate that fluid is leaking from the well, the operator must notify the WOGCC.

The WOGCC requires disclosure of the types and amounts of chemicals used in fracing operations. Operators must submit data to the WOGCC prior to stimulation (WOGCC Chapter 3 § 45(d)); the WOGCC catalogs the data while maintaining the confidentiality of any proprietary information (WOGCC Chapter 3 § 45(f)). However, according to a memorandum issued by the WOGCC, § 45(f) will generally not afford confidentiality protection for well drilling, completion, or stimulation (2010 Memorandum).

The WOGCC also restricts the use of diesel and volatile organic compounds (VOCs) in hydraulic fracturing (WOGCC Chapter 3 § 45(g)) and requires green well completions.

Finally, the WOGCC requires a post-stimulation report, which must include information about the fracing conducted, including the amount of fluids used and several well parameters. (WOGCC Chapter 3 § 45(h)). The operator must also disclose whether fracing fluids are disposed or reused (WOGCC Chapter 3 § 45(j)).

Local Governments

Some local governments are also trying to regulate oil and gas development in general and hydraulic fracturing operations in particular. Examples include:

The city of Grand Junction and the neighboring town of Palisade developed a Watershed Plan with Genesis Gas and Oil (Genesis), which is not legally binding, but addresses citizens’ concerns about oil and gas development. The plan provides that Genesis will use “green” fracing fluids, release the names of the fracing fluid constituents, and inject a tracer with the fracing fluids so that any alleged contamination can be linked to its source. The original watershed plan was a voluntary, collaboratively created document. Grand Junction incorporated it by reference into its watershed ordinance, and now all operators in their watershed must abide by its provisions. More information about this watershed plan can be found on our Community Spotlight page.

The communities of Rifle, Silt, and New Castle developed a Community Development Plan with Antero Resources Corporation and Galaxy Energy, which is not legally binding, but aims to shape how natural gas development occurs in these communities. The plan (1) provides that the oil companies will conduct all hydraulic fracturing with “green” fracing methods and use closed-loop drilling systems; (2) prohibits the use of diesel, petroleum products, and chemicals containing aromatic compounds; and, (3) asks operators to ensure the safety of dams if fracturing takes place. More information about this community development plan can be found on our Community Spotlight page.

Santa Fe County adopted an Oil and Gas Ordinance in 2008. Section 11.25 is entitled “Fracturing and Anodizing.” The ordinance states that fracturing shall not create excess noise levels. In addition, fracturing can only use fresh water. For more information about Santa Fe County’s Oil and Gas Ordinance see our New Mexico County and Municipal Law page.

For more examples of local government actions to regulate oil and gas development, see the Colorado County and Municipal Law page.

Hydraulic Fracturing BMPs

Search the BMP Database

For a customized search of our BMP database on fracing or other processes, click on the Search tab and enter your search keywords.

Several entities, including the BLM, state agencies, and communities, recommend the use of BMPs for hydraulic fracturing. BMPs are generally recommended to address the handling of fracing fluids, reduce traffic and surface disturbances, and protect water quality.

In the News

The United States Government Accountability Office (GAO) released two reports on hydraulic fracturing in September 2012. In the first report, titled Oil and Gas: Informationon Shale Resources, Development, and Environmental and Public Health Risks, GAO investigated the size and growth of the shale gas industry as well as the environmental and public health risks associated with shale gas development.

Some key findings of the report:

- Shale oil production increased more than five-fold from 2007 to 2011, and shale gas production increased more than four-fold from 2007 to 2011.

- Energy Information Administration (EIA) estimates that the amount of technically recoverable shale gas in the United States is 482 trillion cubic feet—an increase of 280 percent from EIA’s 2008 estimate.

- Oil and gas development, whether conventional or shale oil and gas, pose inherent environmental and public health risks, but the extent of these risks associated with shale oil and gas development is unknown, in part, because the studies GAO reviewed do not generally take into account the potential long-term, cumulative effects.

The second report, titled Unconventional Oil and Gas Development: Key Environmental and Public Health Requirements, describes federal and state regulatory requirements and identifies challenges that federal and state agencies face in regulating unconventional gas development.

Some key findings of the report:

- Exemptions in federal regulatory coverage affect the applicability and might limit the effectiveness of environmental and public health laws.

- All of the state programs reviewed by GAO implement additional protective requirements for activities associated with oil and gas development.

- Federal and state agencies reported several challenges in regulating oil and gas development from unconventional reservoirs. EPA officials reported that conducting inspection and enforcement activities and having limited legal authorities are challenges. For example, conducting inspection and enforcement activities is challenging due to limited information, such as data on groundwater quality prior to drilling.

|

According to a recent report by the Pacific Institute, surface spills and leaks, stormwater runoff, and truck traffic impacts on water quality may create greater risks to our water supply than hydraulic fracturing. Visit the Pacific Institute website for the

According to a recent report by the Pacific Institute, surface spills and leaks, stormwater runoff, and truck traffic impacts on water quality may create greater risks to our water supply than hydraulic fracturing. Visit the Pacific Institute website for the